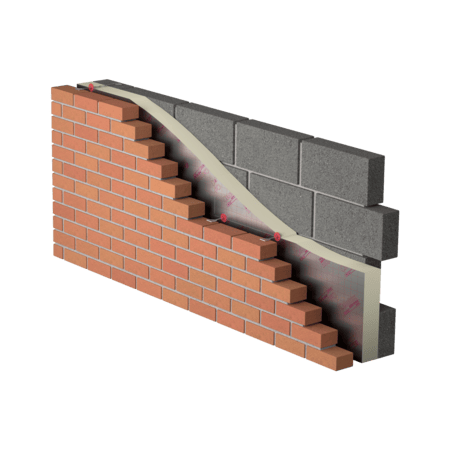

Insulation for Masonry Partial Fill Cavity Walls

For illustrative purposes only

U-value Calculator

Start your U-value calculationBuilding two skins of masonry (brick and/or blockwork) either side of an air cavity has been the most popular method for constructing external walls in the UK for about a century. From its development to address some of the flaws of traditional solid wall construction, it has gradually evolved in response to improving insulation technology and the development of building regulations relating to energy efficiency.

In a partial-fill masonry cavity wall, the residual cavity between the two leaves of masonry is partly filled with a PIR cavity board. Typically a 50mm residual cavity is required to be maintained between the outer face of the cavity insulation and the inner face of the outer leaf.

Key Considerations

When using Celotex products, you need to satisfy yourself that use of the product meets all relevant national Building Regulations and guidance as well as local, national and other applicable standards relevant for your construction or application, including requirements in relation to fire and applicable height restrictions. In addition to the product datasheet, please refer to the following product documents:

- BBA certificates - where applicable to the application

- Declarations of Performance

- Health & safety datasheets

Celotex products should not be used in the external walls of buildings over 11 metres in height. Recent changes to Building Regulations mean that only non-combustible insulation or insulation of limited combustibility should be used in buildings of that height.

The building detail is for illustrative purposes only. It does not constitute advice and should not be relied upon.

Insulation products

| Product Name | Thickness Range | Sizes | Lambda |

|---|---|---|---|

| Celotex CW4000 | 40-100mm | Width 450mm, Length 1200mm | 0.022 |